SMT Assembly is done in our recently updated, state of the art facility. Everything is housed in one location and optimized to accelerate the production process. In this facility we have everything necessary for SMT assembly including stencil printing, pick and place, reflow, cleaning, inspection and X-ray inspection, plus rework.

Stencil Printer

AccuFlex Stencil Printer

An AccuFlex stencil printer combines high accuracy in laying down solder paste for low to medium board runs. The AccuFlex printer is designed for production of about 8,000 boards per week. The system handles boards from 3″ x 2″ to 23″ x 20″ and is capable of printing 12-mil pitch devices with consistent accuracy. AccuFlex’s 6 sigma accuracy ensures precise and repeatable printing capability with an 11 second cycle time that enhances line productivity.

Pick and Place

MyData Pick and Place Machine

A Mydata 10LXE combined with the Agilis feeder system is used for the pick and placement of components. The 100LXE has high placement and speed accuracy and is rated at 13,000 chips per hour. The component range of the machine starts as low as 0201, but it can also handle large components like DPAKs, BGAs, PLCCs, QFPs and surface mount connectors. The Agilis feeder systems provides intelligent feeders and magazines that cover tape, stick and tray carriers. Overall, the system allows the flexibility and speed needed to build all of our power supply designs.

Solder Reflow

IBL SLC-309 Vapour Phase solder reflow

Reflow is managed by an IBL SLC-309. The SLC-309 employs soft Vapour Phase technology. The SLC-309 uses the heat transfer from Vapour (from a chosen liquid based on its boiling point) that condenses on the PCB board to reflow the solder. Vapour Phase reflow allows for the lowest possible maximum temperatures that cannot overheat components, while providing an inert (oxygen free) atmosphere. Furthermore, we use Soft Vapour Temperature Control (SVTC) to not only control the time a board remains at a particular temperature, but also allows us to control the temperature of the PCB at any given level, allowing for precisely controlled profiles.

Aqueous Cleaning

Aqueous Technologies Trident XLD cleaning system

The Cleaning of PCBs is controlled by a Trident XLD cleaning system by Aqueous Technologies. The Trident XLD is an automatic defluxing and cleanliness testing system. The system provides an onboard cleanliness testing system that can be programmed to a desired cleanliness level.

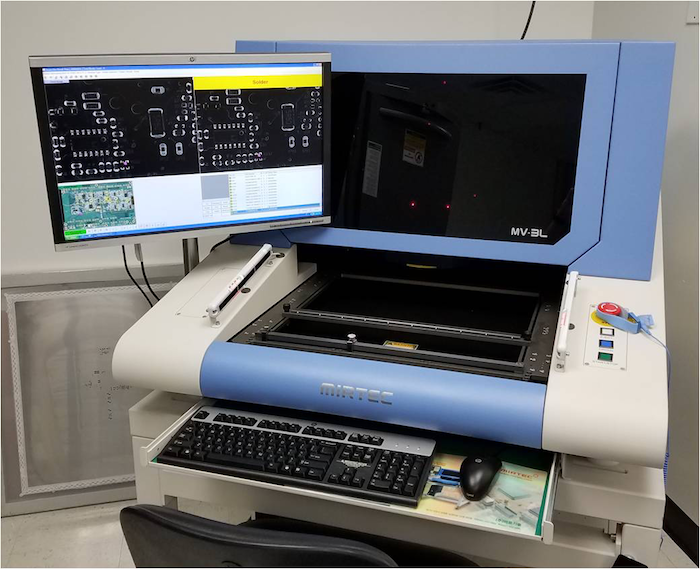

Optical Inspection

Mirtek MV-3L automatic optical inspection

AOI (Automatic Optical Inspection) is handled by a Mirtek MV-3L. The MV-3L is equipped with five, 5 mega pixel cameras that provide five separate images of the component. The multiple images allow for top and side view inspection of the component. The AOI machine facilitates the inspection of component polarity, part marking, component presence/absence, lifted leads, tombstoning and much more. In addition, the MV-3L has an enhanced solder joint and solder bridge functionality allowing for the inspection of solder joints.

X-Ray Inspection

Glenbrook Technologies JewelBox-70T X-ray inspection system

X-ray inspection is handled by a Glenbrook Technologies JewelBox-70T inspection system. The system delivers superior image quality with excellent resolution and sensitivity for laboratory and failure analysis applications. The system’s 10-micron MicroTech™ x-ray source provides magnification from 7X to 2000X, with resolution of 100 line pairs/mm.

The JewelBox inspection systems comes with the pre-installed GTI Processing Workstation. The extensive features of the GTI-5000, including Auto-BGA and void measurement, make the JewelBox-70T an ideal laboratory and production instrument to inspect electronic components.

Rework

Rework is accomplished using the Metcal Scorpion APR-1200-SRS. The Scorpion rework system ensures accurate component placement with custom tailored reflow profiles. The APR-1200-SRS uses a new vision system that employs a dual image overlay technology that allows for the precise alignment of the smallest BGAs, QFNs and Micro SMDs with the highest accuracy.